Bangladesh makes millions of t-shirts every year. The country is one of the biggest clothing makers in the world. Quality control Bangladesh t-shirt supplier practices help make sure every shirt meets high standards. Good quality control keeps customers happy and builds trust with brands worldwide.

Why Quality Control Matters for Bangladesh T-shirt Suppliers

Quality control helps Bangladesh t-shirt makers deliver great products every time. When suppliers check their work carefully, customers get shirts that look good and last long. This builds strong relationships between buyers and suppliers.

Good quality control also protects brand reputation. When a best t-shirt manufacturer in Bangladesh follows strict quality rules, brands can trust their products. This trust leads to more orders and better business partnerships.

High-quality t-shirts from Bangladesh compete well in world markets. Countries like USA, UK, and Europe buy billions of shirts from Bangladesh each year. Quality control helps these suppliers stand out from competitors in other countries.

Supplier Audits and Certification

Supplier audits check whether factories follow good practices. These checks look at machines, workers, and production methods. Audits help buyers know which suppliers they can trust.

International certifications prove that suppliers meet world standards. These certificates show that factories follow safe and fair practices. Buyers often require these certifications before placing large orders.

Regular audits ensure consistent quality over time. They catch problems early before they affect production. This saves time and money for both suppliers and buyers.

Key Certifications to Look For in Bangladesh T-shirt Suppliers

ISO 9001 – This certification shows good quality management systems. It proves factories have proper processes in place.

GOTS (Global Organic Textile Standard) – This standard covers organic fabric production. It ensures eco-friendly manufacturing practices.

BSCI (Business Social Compliance Initiative) – This certification focuses on worker rights and safety. It shows factories treat employees fairly.

| Certification | Focus Area | Benefits | Validity Period |

|---|---|---|---|

| ISO 9001 | Quality Management | Better processes, consistent quality | 3 years |

| GOTS | Organic Textiles | Eco-friendly production, organic materials | 1 year |

| BSCI | Social Compliance | Worker safety, fair labor practices | 2 years |

| OEKO-TEX | Chemical Safety | Safe fabrics, no harmful chemicals | 1 year |

| WRAP | Workplace Standards | Ethical manufacturing, worker rights | 2 years |

Fabric Quality and Sourcing

Good fabric makes good t-shirts. The type and quality of fabric affects how shirts look, feel, and last. Quality control Bangladesh t-shirt supplier companies test fabrics before using them in production.

Bangladesh has both local and imported fabrics available. Local cotton is often cheaper but imported fabrics might offer better quality. Smart suppliers choose the right fabric for each order.

Quality checks include testing fabric strength, color, and shrinkage. These tests happen before cutting and sewing begins. This prevents problems later in production.

Common Fabrics Used in Bangladesh T-shirt Manufacturing

Cotton – Natural fiber that feels soft and breathes well. Most popular choice for basic t-shirts.

Polyester – Synthetic fiber that dries quickly and keeps colors bright. Good for sports and performance wear.

Blends – Mix of cotton and polyester that combines benefits of both materials. Offers good comfort and durability.

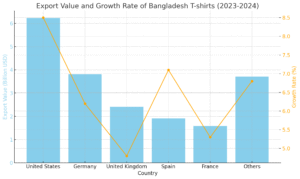

Bangladesh T-shirt Export Statistics (2023-2024)

5 Ways to Ensure Quality control Bangladesh t-shirt supplier

1. Conduct Regular Supplier Audits

Check factories often to make sure they follow quality rules. Look at machines, workers, and production areas. This helps find problems before they affect your orders.

2. Verify Fabric Quality Before Production

Always test fabric samples first. Check if colors stay bright after washing. Test whether the fabric shrinks or stretches beyond acceptable limits. This prevents quality issues in finished shirts.

3. Implement In-line Quality Checks

Watch production while it happens. Check stitching, printing, and cutting during manufacturing. Catch mistakes early when they are easier to fix.

4. Test Final Products in Accredited Labs

Send finished t-shirts to testing labs. These labs check durability, color fastness, and sizing accuracy. Lab reports prove quality to buyers.

5. Monitor Packaging and Shipment Quality

Check how shirts are packed and shipped. Make sure packaging protects shirts during transport. Good packaging keeps shirts looking new when they arrive.

Skilled Workforce and Training Programs

Bangladesh has many skilled garment workers. These workers know how to make quality t-shirts efficiently. Why choose Bangladesh t-shirt supplier options often include access to this skilled workforce.

Training programs help workers learn new skills and improve quality. Regular training reduces mistakes and improves productivity. Well-trained workers make better products consistently.

Happy workers make better quality products. Factories with good working conditions often have higher quality output. Worker satisfaction directly impacts product quality.

How Labor Conditions Impact Product Quality

Safe working environments – Clean, safe factories help workers focus on quality. Good lighting and ventilation improve work accuracy.

Employee morale and quality outcomes – Happy workers take more pride in their work. This leads to better attention to detail and fewer mistakes.

Testing and Product Sampling

Pre-shipment samples let buyers check quality before receiving full orders. These samples show actual product quality and help catch any issues. Most quality control Bangladesh t-shirt supplier companies provide samples automatically.

Lab testing checks important quality factors like durability and colorfastness. These tests use international standards to measure quality. Test reports give buyers confidence in product quality.

Customer feedback helps improve future production. Good suppliers listen to buyer comments and make improvements. This creates better products over time.

Quality Control Test Comparison

| Test Type | Industry Standard | Acceptable Range | Test Duration | Cost Level |

|---|---|---|---|---|

| Tensile Strength | ASTM D5034 | 200-400 N | 2 hours | Low |

| Color Bleeding | ISO 105-C06 | Grade 4-5 | 4 hours | Medium |

| Shrinkage | AATCC 135 | <3% | 24 hours | Medium |

| Pilling Resistance | ASTM D3512 | Grade 4+ | 8 hours | High |

| Colorfastness to Light | ISO 105-B02 | Grade 4+ | 48 hours | High |

Frequently Asked Questions (FAQ)

1. What is the typical lead time for quality-controlled t-shirt production in Bangladesh?

Most quality control Bangladesh t-shirt supplier companies need 15-25 days for standard orders. This includes fabric testing, production, and quality checks. Rush orders may take 10-12 days but cost more. Complex designs or special fabrics need extra time.

2. How much does quality testing add to the t-shirt cost?

Quality testing usually adds 2-5% to the total order cost. Basic tests like shrinkage and colorfastness cost less. Advanced tests like chemical analysis cost more. Most buyers find this small cost worth the quality assurance benefits.

3. What minimum order quantity do Bangladesh t-shirt suppliers require?

Most suppliers require 500-1000 pieces minimum per design. Larger factories may need 2000+ pieces. Smaller suppliers can handle 200-300 pieces but at higher unit prices. Quality control costs are spread across the order size.

4. Can I visit Bangladesh factories to check quality control systems?

Yes, most reputable suppliers welcome factory visits. This helps buyers see quality control processes firsthand. Plan visits during production hours to see actual operations. Many suppliers offer virtual factory tours as well.

5. What happens if quality control tests fail?

Good suppliers will remake failed products at no extra cost. They should identify why tests failed and fix the problem. Some suppliers offer partial refunds or discounts for minor quality issues. Always agree on quality standards before production starts.

Conclusion

Quality control Bangladesh t-shirt supplier practices are essential for success in global markets. Good quality control helps suppliers build trust with international buyers. It also ensures customers get products they love and want to buy again.

Brands should work with suppliers who have strong quality systems. Look for certifications, testing procedures, and skilled workers. These factors indicate a supplier who cares about quality.

Custom t-shirt printing Bangladesh services also benefit from good quality control. Whether making basic shirts or custom designs, quality control ensures great results every time.

Smart buyers also consider ethical sourcing Bangladesh t-shirt manufacturing practices. Ethical suppliers often have better quality control because they care about all aspects of their business.

Call-to-Action

Ready to source quality t-shirts from Bangladesh suppliers? Learn how to choose the best Bangladesh t-shirt supplier for bulk orders and start building successful partnerships today.

Contact experienced quality control Bangladesh t-shirt supplier companies who understand international quality standards and can deliver the products your customers expect.