The cost comparison us vs overseas clothing manufacturing is a critical decision that shapes the future of fashion brands worldwide. In 2025, startups, direct-to-consumer (DTC) brands, and global retailers are carefully examining where to produce their garments. The choice between manufacturing in the United States or overseas locations like Bangladesh, China, Vietnam, and India affects pricing, quality, delivery speed, and brand identity. This analysis explores real industry data, sourcing experience, and supply-chain trends to help you make informed decisions.

Understanding Cost comparison us vs overseas clothing manufacturing

Before diving into specific locations, you need to understand what makes up the total cost of producing clothing. Manufacturing costs are not just about paying workers – they include multiple layers of expenses that can dramatically change your final price.

Labor Costs in Cost Comparison US vs Overseas Clothing Manufacturing

Labor represents the biggest difference between US and overseas production. In the United States, the federal minimum wage is $7.25 per hour, but garment workers typically earn between $12-$20 per hour in major manufacturing states. Skilled workers like pattern makers or quality control specialists can command $25-$40 per hour.

Compare this to overseas markets: In Bangladesh, average garment worker wages range from $0.50-$1.20 per hour. Vietnam offers slightly higher rates at $1.50-$2.50 per hour, while China has increased to $3-$6 per hour in industrial zones. India falls somewhere in the middle at $1-$2.50 per hour.

Raw Material Costs in Cost Comparison US vs Overseas Clothing Manufacturing

Fabric sourcing plays a major role in your final expenses. The US has limited textile mills, so many brands import fabrics even for domestic production, adding freight costs. Countries like Bangladesh and China have extensive textile ecosystems where fabric mills, dyeing facilities, and garment factories operate in close proximity.

Local material sourcing in Asia cuts transportation costs and reduces lead times between fabric production and garment assembly. A t-shirt made in Bangladesh can use locally-produced cotton fabric at 30-40% lower cost than imported materials.

Overhead & Compliance Costs in Cost Comparison US vs Overseas Clothing Manufacturing

Factory overhead includes rent, utilities, machinery maintenance, and insurance. US factories face higher real estate costs, expensive electricity rates, and comprehensive insurance requirements. A 10,000 square foot factory in Los Angeles might cost $15,000-$25,000 monthly in rent alone.

Overseas facilities in industrial zones benefit from government subsidies, lower utility rates, and reduced property costs. Legal compliance in the US involves strict OSHA regulations, environmental standards, and labor laws that increase operational expenses but ensure worker safety.

Cost Comparison US vs Overseas Clothing Manufacturing: United States Breakdown

Labor & Wage Expenses in Cost Comparison US vs Overseas Clothing Manufacturing

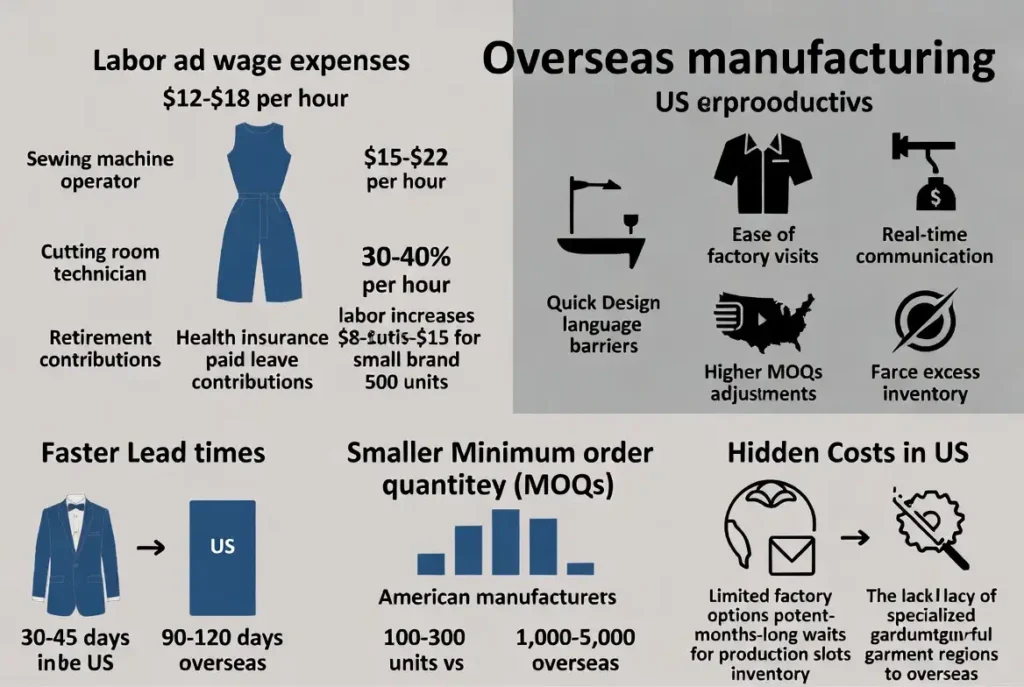

American garment workers bring skills and experience that justify higher wages. A sewing machine operator in the US earns approximately $12-$18 per hour, while a cutting room technician makes $15-$22 per hour. When you add benefits like health insurance, paid leave, and retirement contributions, the true cost per employee rises by 30-40%.

Union representation in some US factories adds another layer of costs. While unions protect workers and maintain quality standards, they increase labor expenses through negotiated wages, benefits, and working conditions. For a small brand producing 500 units, US labor alone can add $8-$15 per garment.

Domestic Production Advantages in Cost Comparison US vs Overseas Clothing Manufacturing

Manufacturing in America offers speed and flexibility that overseas production cannot match. Lead times shrink from 90-120 days to just 30-45 days. You can visit factories easily, communicate in real-time without language barriers, and make quick adjustments to designs.

Smaller minimum order quantities (MOQs) are more accessible in the US. While overseas factories often require 1,000-5,000 piece minimums, American manufacturers might accept orders as small as 100-300 units. This flexibility helps new brands test markets without huge upfront investments.

Hidden Costs in US Manufacturing for Cost Comparison US vs Overseas Clothing Manufacturing

American factories are not as abundant as they once were, creating limited options for brands. You might wait months for production slots at preferred facilities. Higher MOQs at certain factories force brands to order more inventory than needed, tying up cash flow. The specialization that exists overseas – where entire regions focus on specific garment types – is harder to find in the US market.

Cost Comparison US vs Overseas Clothing Manufacturing: Overseas Production Breakdown

Labor Savings in Cost Comparison US vs Overseas Clothing Manufacturing

Overseas manufacturing delivers dramatic cost reductions through lower wages. Bangladesh stands out as the most affordable option, where a basic t-shirt might cost $2-$3 to produce compared to $8-$12 in the US. Vietnam follows closely with competitive pricing and improving infrastructure.

Here is a wage comparison across major manufacturing countries:

| Country | Average Hourly Wage | Monthly Garment Worker Salary |

|---|---|---|

| United States | $12-$20 | $2,080-$3,200 |

| Bangladesh | $0.50-$1.20 | $85-$200 |

| Vietnam | $1.50-$2.50 | $250-$420 |

| China | $3-$6 | $520-$1,000 |

| India | $1-$2.50 | $170-$420 |

These wage differences mean a hoodie that costs $25 to produce in Los Angeles might only cost $6-$8 in Dhaka, Bangladesh, before shipping and duties.

Factory Scale & Efficiency in Cost Comparison US vs Overseas Clothing Manufacturing

Asian factories operate at massive scales that create economies of efficiency. A single factory in Bangladesh might employ 2,000-5,000 workers across multiple production lines. This scale allows specialization where workers perfect specific tasks, increasing speed and consistency.

Automation and modern machinery in countries like China and Vietnam further reduce per-unit costs. Assembly line optimization, computerized cutting systems, and automated quality checks mean faster production with fewer errors.

Risks in Overseas Manufacturing for Cost Comparison US vs Overseas Clothing Manufacturing

Distance creates challenges in communication and oversight. Time zone differences mean waiting 12-15 hours for email responses. Language barriers can lead to misunderstandings about design specifications, causing costly mistakes. Political instability, labor strikes, or economic shifts in manufacturing countries can disrupt production schedules unexpectedly.

Shipping, Logistics, and Duties in Cost Comparison US vs Overseas Clothing Manufacturing

Freight Costs in Cost Comparison US vs Overseas Clothing Manufacturing

Moving finished garments from Asia to the US adds significant expenses. Sea freight is economical but slow, taking 30-45 days from Bangladesh or Vietnam. A 40-foot container holding approximately 10,000-15,000 t-shirts costs $3,000-$8,000 depending on fuel prices and demand.

Air freight accelerates delivery to 5-7 days but costs 5-10 times more than ocean shipping. Brands rush-ordering products for unexpected demand spikes can spend $4-$8 per kilogram, dramatically reducing profit margins. Shipping costs fluctuate based on oil prices, carrier availability, and seasonal demand.

Import Duties & Tariffs in Cost Comparison US vs Overseas Clothing Manufacturing

US Customs applies import duties to clothing based on Harmonized System (HS) codes. Most apparel faces 16-32% duty rates. A shipment of dresses valued at $10,000 might incur $1,600-$3,200 in duties. Some countries benefit from trade agreements offering reduced or zero duties, making them more attractive sourcing destinations.

Cotton clothing typically faces different duty rates than synthetic blends. Understanding HS codes and working with customs brokers prevents costly classification errors.

Lead Time & Delays in Cost Comparison US vs Overseas Clothing Manufacturing

Port congestion at major US entry points like Los Angeles, Long Beach, and New York can add 1-3 weeks to delivery schedules. Customs clearance requires proper documentation, inspection, and duty payment, taking 3-7 days for routine shipments. Errors in paperwork or random inspections can extend delays to several weeks, putting seasonal collections at risk.

Quality Control & Production Reliability in Cost Comparison US vs Overseas Clothing Manufacturing

Quality Assurance in Cost Comparison US vs Overseas Clothing Manufacturing

Maintaining consistent quality across thousands of units requires rigorous inspection systems. US factories allow easy on-site visits where you can examine production in person. Overseas manufacturing demands third-party inspection services that cost $200-$500 per factory visit.

Pre-production samples, in-line checks during manufacturing, and final random inspections help catch defects before shipping. Brands working with Bangladesh garment factories often hire local quality control firms to monitor production standards.

Rework & Defect Costs in Cost Comparison US vs Overseas Clothing Manufacturing

Defective products create multiple layers of expense: the cost of the flawed item, shipping expenses, potential customer refunds, and brand reputation damage. A 5% defect rate on a 10,000 unit order means 500 pieces need replacement or discounting. If each piece costs $5 to produce and ship, that represents $2,500 in direct losses.

Returns from customers add shipping costs, restocking labor, and inventory management challenges. High-quality production prevents these cascading expenses that eat into profit margins.

Ethical, Sustainability & Compliance Factors in Cost Comparison US vs Overseas Clothing Manufacturing

Labor Ethics in Cost Comparison US vs Overseas Clothing Manufacturing

Fair treatment of garment workers is not just morally right – it affects brand reputation and customer loyalty. Younger consumers, particularly Gen Z aged 15-18, increasingly research brand ethics before purchasing. US manufacturing guarantees compliance with federal labor laws including minimum wage, overtime pay, and safe working conditions.

Overseas production requires diligent factory audits to ensure ethical standards. Reputable manufacturers in Bangladesh, like those certified by international compliance standards, maintain fair wages and safe environments. Brands must verify working conditions through third-party audits and factory certifications.

Environmental Regulations in Cost Comparison US vs Overseas Clothing Manufacturing

Carbon footprint calculations increasingly influence sourcing decisions. Shipping garments 8,000 miles from Asia generates significant emissions. US production reduces transportation pollution but faces higher energy costs for manufacturing operations.

Sustainable manufacturing practices like water recycling, renewable energy use, and waste reduction are easier to verify in domestic factories. Overseas facilities vary widely, with some adopting cutting-edge green technology while others lag behind environmental standards.

Small Brands vs Large Brands in Cost Comparison US vs Overseas Clothing Manufacturing

Startup Perspective in Cost Comparison US vs Overseas Clothing Manufacturing

New brands face tight budgets and uncertain demand. Ordering 5,000 hoodies from an overseas factory might offer the lowest per-unit cost but requires $15,000-$30,000 upfront investment. If those hoodies do not sell, the brand is stuck with dead inventory.

US manufacturing allows testing with smaller runs of 100-300 units. While per-piece costs are higher at $12-$18 instead of $5-$7, the total cash outlay is manageable at $1,200-$5,400. This flexibility lets startups validate designs before committing to large production runs.

Enterprise-Level Strategy in Cost Comparison US vs Overseas Clothing Manufacturing

Established brands with proven demand leverage overseas production for volume discounts. An order of 50,000 polo shirts brings per-unit costs down through bulk material purchases and dedicated production lines. Large retailers often maintain relationships with factories across multiple countries, diversifying risk and optimizing costs based on garment type.

Multi-country sourcing means producing basic items like t-shirts in Bangladesh for cost efficiency while manufacturing technical athletic wear in Vietnam or China where specialized expertise exists.

Real Cost Comparison US vs Overseas Clothing Manufacturing Example (Case Study)

Let me break down actual costs for producing 1,000 basic cotton t-shirts:

US Manufacturing (Los Angeles):

- Labor: $6.50 per unit

- Materials: $3.00 per unit

- Overhead: $1.50 per unit

- Total: $11.00 per unit

- 1,000 units = $11,000

Overseas Manufacturing (Bangladesh):

- Labor: $1.20 per unit

- Materials: $2.10 per unit

- Overhead: $0.70 per unit

- Shipping: $1.00 per unit

- Duties (18%): $0.90 per unit

- Total: $5.90 per unit

- 1,000 units = $5,900

The overseas option saves $5,100 on this order, nearly cutting costs in half. For a brand selling these t-shirts at $25 retail, US manufacturing yields $14 gross profit per unit while overseas production generates $19.10 profit per unit – a 36% improvement in margin.

Which Option Is Best Based on Cost Comparison US vs Overseas Clothing Manufacturing?

US manufacturing makes sense when:

- You need quick turnaround (under 45 days)

- Order quantities are small (under 500 units)

- Design changes happen frequently

- Premium “Made in USA” positioning justifies higher prices

- Direct factory oversight is critical

Overseas manufacturing is more cost-effective when:

- Order volumes exceed 1,000 units

- Lead times of 90-120 days are acceptable

- Cost savings are the primary concern

- You have established quality control systems

- Product designs are finalized before production

Hybrid models combine both approaches: produce core, high-volume items like basic t-shirts overseas while manufacturing limited editions, custom orders, or trend-responsive pieces domestically.

Final Verdict on Cost Comparison US vs Overseas Clothing Manufacturing

The cost comparison us vs overseas clothing manufacturing reveals that overseas production typically offers 40-60% cost savings on labor-intensive garments. For brands prioritizing affordability and volume, countries like Bangladesh provide unmatched value. US manufacturing suits brands valuing speed, flexibility, and domestic production appeal.

Strategic sourcing planning means matching each product category to the most appropriate manufacturing location. Consider your brand stage, target customer values, product complexity, and cash flow capacity. The right choice balances cost efficiency with operational requirements and brand positioning.

Ready to Start Your Clothing Manufacturing Journey?

Texasia specializes in high-quality, cost-effective garment production in Bangladesh. Whether you need kidswear, athletic wear, denim jeans, or custom printed apparel, our experienced team delivers exceptional results. We maintain international quality standards, ethical labor practices, and competitive pricing that helps your brand succeed. Visit Texasia.com to explore our full range of manufacturing services and start your production partnership today.